Adhering to the sustainable development principles, Ripple Energy Resources is striving to boost the value of the company, increase the return on investment, and to deliver high-quality products and services.

Read MoreCall Us For Quote

Get your quality products from Ripple Energy Resources

+7 707 569 5290

Crude Oil

With a crude oil refining capacity of 3 million barrels per calendar day in our refinery system, Ripple Energy Resources plays a significant role providing refined products that you use every day.

Our refineries are integrated with our midstream assets to maximize operating efficiency. The transportation links that connect our refineries allow the movement of intermediate products between refineries to optimize operations, produce higher margin products and efficiently utilize our processing capacity.

In recent years, the Company's refining activities have been focused on meeting the market demand for quality petroleum products.

Over the years, Ripple Energy Resources has been consistently implementing a programme to modernise its refineries, which has enabled it to expand its product range, improve the quality of its products and increase its competitiveness. This is the most ambitious programme of modernization of oil refining capacities in the Kazakhstan oil industry. In the course of implementation of this program, since the end of 2018, the transition to 100% production of motor fuels of environmental class K5 for the domestic market of Kazakhstan has been made, in accordance with the requirements of the Technical Regulations of TR TS 013/2011. Since 2020, a number of the Company's refineries have been producing motor gasoline with improved environmental and operational properties of AI-95-K5 Euro-6 and AI-100-K5.

Ripple Energy Resources also owns stakes in a number of refining assets abroad: in Kazakhstan, Germany, Belarus, China and India.

Treatment

The finishing touches occur during the final treatment. To make gasoline, refinery technicians carefully combine a variety of streams from the processing units. Octane level, vapor pressure ratings, and other special considerations determine the gasoline blend.

Storage

Both incoming crude oil and the outgoing final products are stored temporarily in large tanks on a tank farm near the refinery. Pipelines, trains, and trucks carry the final products from the storage tanks to locations across the country.

Bitumen (Asphalt)

We produce and also acquire bulk Bitumen in Vessels with volumes comprising around 30,000 Metric Tons each Cargo directly from Bitumen Manufacturers either they are Bitumen Refineries (VB Based) or State of the Art Oil Refinery. Being financially competitive in manufacturing market means meeting deadlines and constantly striving to Increase Production, Reduce Downtime and Maintain Product Quality. Our Buyers are Bulk Consumers of Bitumen like Construction and Infrastructure Development Companies, Importers of Bitumen willing to supply locally in their countries.

Mainly, Our Buyers are Bulk Consumers of Bitumen like Construction and Infrastructure Development Companies, Importers of Bitumen willing to supply locally in their countries. We have 20 Years of Asphalt/Tar/Bitumen and Cement Export history.

Overview of Refined Bitumen

Bitumen is an Oil Based substance. It is a Semi-Solid Hydrocarbon Product produced by removing the Lighter Fractions (such as Liquid Petroleum Gas, Petrol and Diesel) from Heavy Crude Oil during the Refining process. As such, it is correctly known as Refined Bitumen.

The vast majority of Refined Bitumen is used in Construction: primarily as a constituent of products used in paving and roofing applications. According to the requirements of the end use Bitumen is produced to specification. This is achieved either by refining process or blending.

It is estimated that the current world use of Bitumen is approximately 102 million tons per year. Approximately 85% of all the Bitumen produced is used as the Binder in Asphalt for roads. It is also used in other paved areas such as Airport Runways, Car Parks and Footways.

Aviation Fuel

Jet fuel is a kerosene-based fuel similar to diesel and is the leading aviation fuel type for turbine-engine aircraft – from commercial jets to cargo aircraft, military airplanes and more. It is generally more stable and more widely available than avgas, with different properties that make it more suited to jet engines and to flying through different climactic conditions.

We have jet fuel varieties made from either unleaded kerosene (Jet A and Jet A-1) or a naphtha-kerosene blend (Jet B).

Contamination risks for Jet A1 fuel

Because of its kerosene base, Jet A1 fuel is less volatile than Avgas and can generally be stored for longer – particularly in the right conditions.

But it’s still vulnerable to common causes of fuel contamination.

D6 Diesel Bunker Fuel

Also Known As Virgin Fuel Oil / Residual Fuel Oil / Bunker Oil.

D6 Diesel is also known as Residual Fuel Oil / Bunker Fuel Oil , Bunker Oil and is of high-viscosity. This particular fuel oil requires preheating to 220 – 260 Degrees Fahrenheit. D6 is mostly used for generators.

D6 is a type of residual fuel, mainly used in power plants and larger ships. The fuel requires to be preheated before it can be used. It is not possible to use it in smaller engines or vessels/vehicles where it is not possible to pre-heat it.

Residual means the material remaining after the more valuable cuts of crude oil have boiled off. The residue may contain various undesirable impurities including 2 percent water and one-half percent mineral soil. D6 fuel is also known as residual fuel oil (RFO), by the Navy specification of Bunker , or by the Pacific Specification of PS-400.

Recent changes in fuel quality regulation now require further refining of the D6 in order to remove the sulfur, which leads to a higher cost.

The price of D6 diesel traditionally rises during colder months as demand for heating oil rises, which is refined in much the same way. In many parts of the Kazakhstan, D6 diesel may be priced higher than petrol.

D6 Diesel Standards and Classification

Despite this marine fuels are still quoted on the international bunker markets with their maximum viscosity (which is set by the ISO 8217 standard – see below) due to the fact that marine engines are designed to use different viscosity's of fuel.

The unit of viscosity used is the Centistoke and the d6 fuel most frequently quoted are listed below:

D2 Gas Oil

D2 is a refinery abbreviation for Gasoil. It is the second distillate from the crude oil, and can be used without reformers and additives. So, the first engines used D2 as fuel before petrol cars as we know them today was invented. That is because the engine invented by a German called Diesel, requires no spark plugs. The diesel engine will ignite and combust when the pressure increases so that the heated “plug” makes it explode. Here we get the name “Diesel” since the same principles are used in diesel engines today. However, automotive diesel that you fill has additives that the refinery will add to make the engine more efficient and also easier to start in the winter. Diesel changes “flash point” in the winter. It also has additives to absorb water that condense. If you use summer diesel in the winter, you will get better mileage, but your fuel pipes may freeze and can also burst, and the wax makes the diesel flow thicker.

D2 is the second distillate from the crude oil, and can be used without reformers and additives. So, the first engines used D2 as fuel before petrol cars as we know them today was invented. That is because the engine invented by a German called Diesel, requires no spark plugs. The diesel engine will ignite and combust when the pressure increases so that the heated “plug” makes it explode. Here we get the name “Diesel since the same principles are used in diesel engines today.

However, automotive diesel that you fill has additives that the refinery will add to make the engine more efficient and also easier to start in the winter. Diesel changes “flash point” in the winter. It also has additives to absorb water that condense. If you use summer diesel in the winter, you will get better mileage, but your fuel pipes may freeze and can also burst, and the wax makes the diesel flow thicker.

So “Low sulphur Gasoil” is no longer 4 percent but below 0.2 percent. Then we have a new, “Ultra Low Sulphur” at 0.02% at the most, and the limit here is (a) that mass spectographs requires extensive calibration to measure below 1000ppm, and (b) sulphur has a way to form clogs the molecules binds to free hydrogen molecules and form a cluster of molecules that will break if “cracked” by the refinery, but as explained above, D2 is a distillate and has not been “cracked”.

Automotive diesel has national variants but the usual variants traded are EN590 and EN560 which are specified by ISO in Paris. Automotive diesel is now tested in planes with great success, where you get greater mileage per weight unit of fuel as much as 40% increase. In these days, when no stone remains unturned to reduce emissions, one outcome may be that planes will fly on Gasoil and not kerosene. The problem is condensate / ice particles and wax that may cause the jet engine (which is a turbine) to be completely destroyed. A preliminary solution is to heat the gasoil before injection, and pass it through an electrostatic filter.

Engine Oil

Engine oil grades denote critical viscosity and performance specifications, allowing the selection of the optimal formula to match operating conditions. Understanding the different engine oil types allows drivers and mechanics to select the optimal oil viscosity and formulation to match their vehicle's engine and operating conditions.

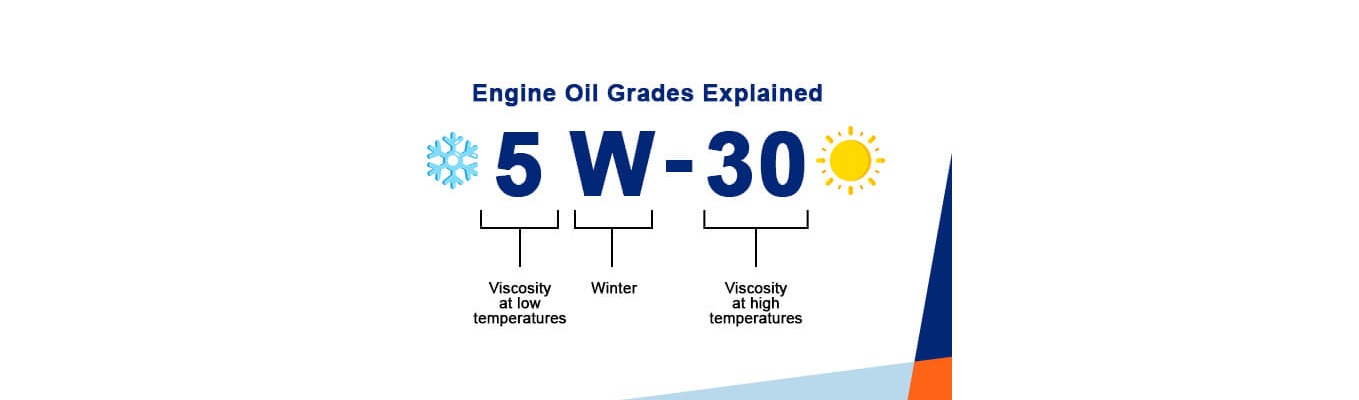

How to Read Engine Oil Grade?

The SAE system classifies engine oil viscosity grades like 5W-30. The first number denotes winter/cold flow grade - lower means easier pumping when cold. After the "W," the second number reflects hot operating viscosity - higher indicates thicker oil that better retains film strength under heat. This numbering conveys an oil's flow at temperature extremes.

Relevance in the Automotive Industry

Engine oil grade classifications evolved in the automotive space as multi-viscosity oils were developed to replace single-grade types. This allowed superior protection across diverse operating conditions in modern engines. Specifying oil grades by SAE viscosity ratings has become the global industry standard when defining engine oil performance criteria.

Understanding Motor Oil Classifications

The API oversees a motor oil grading system certifying performance levels for gasoline and diesel engines. "S" classifications denote petrol engine oils, while "C" ratings denote diesel oils. These letters are followed by standards indicating the performance category and year introduced, such as SN for 2021 petrol engine specifications.

SAE defines vital oil testing protocols and sequences to qualify overall engine oil quality and performance.

Types of Engine Oil Grades

Engine oils come in single-grade and multi-grade formulas, with fundamental differences in their temperature operating ranges. Multi-viscosity oils using viscosity index improvers provide the most robust protection across diverse climates.

Single-Grade vs Multi-Grade Oils

How to Choose the Right Engine Oil?

When selecting engine oil, keep these essential steps in mind:

Coke

Petroleum coke is a carbon rich solid by-product of the crude oil refinery process. “Petcoke” for short, is a substance that can be hard or relatively soft and has a porous texture with a likeness to coal. It is produced from both fluid and delayed coking operations and is often utilised as a low-grade fuel, cement and in the production of aluminium and steel.

Whilst Petcoke can be of some value, the build-up of the substance can occur on critical equipment as a scale and can be detrimental to the overall production process.

At Ripple Energy Resources, we have utilised our expertise to develop a pioneering solution, Petrox, that can effectively remediate the loss of efficiency in the refinery process, whilst ensuring cost effectiveness and well-maintained safety at all times. This ultimately will result in minimal downtime and decreased environmental, health and safety risks.

Not only is Petrox less aggressive than a variety of other acid-based products, ensuring it safe to use on a variety of metals and acid resistant surfaces but it is non-fuming, making it substantially more user friendly. It can be diluted with water over a range of concentrations, meaning that it is suitable for many different application methods and surfaces including heat exchangers.

Petroleum coke is highly valued for its carbon content and energy density, making it useful in various industrial applications. The high carbon content makes petcoke suitable for use in industries requiring high purity carbon materials, such as in the production of anodes for aluminum and steel production.

The physical properties of petcoke make it highly useful in various industrial applications, with the material serving both as an energy source and a raw material for producing electrodes used in aluminum and steel industries. Moreover, petcoke is increasingly being used in power generation, cement manufacturing, and other energy-intensive industries. However, its combustion and environmental implications are under increasing scrutiny due to its high carbon content and the emission of pollutants.

Types of Petroleum Coke

Petroleum coke can be classified into different types based on its microstructure and physical properties. The four main types of petroleum coke are: (A) Needle Coke, (B) Honeycomb Coke, (C) Sponge Coke & (D) Shot Coke.

Liquefied Natural Gas (LNG)

Liquefied natural gas (LNG) is natural gas that has been cooled to a liquid state, at about -260°Fahrenheit, for shipping and storage. The volume of natural gas in its liquid state is about 600 times smaller than its volume in its gaseous state. This process, which was developed in the 19th century, makes it possible to transport natural gas to places pipelines do not reach and to use natural gas as a transportation fuel.

For large-volume ocean transport, LNG is loaded onto double-hulled ships, which are used for both safety and insulating purposes. Once the ship arrives at the receiving port, LNG is off-loaded into well-insulated storage tanks, and later regasified for entrance into a pipeline distribution network.

LNG can also be shipped in smaller quantities, usually over shorter ocean distances. There is a growing trade in small-scale LNG shipments, which are most commonly made using the same containers used on trucks and in international trade, specially outfitted with cryogenic tanks. Other small-scale LNG activities include “peak-shaver” liquefaction and storage facilities, which can hold gas compactly for when it is needed in local markets in the Kazakhstan during times of peak demand. LNG is also sometimes imported or exported by truck from this kind of facility.

Liquefied natural gas (LNG) is natural gas that has been cooled to a liquid state, at about -260° Fahrenheit, for shipping and storage. The volume of natural gas in its liquid state is about 600 times smaller than its volume in its gaseous state. This process makes it possible to transport natural gas to places pipelines do not reach.

Liquefying natural gas is a way to move natural gas long distances when pipeline transport is not feasible. Markets that are too far away from producing regions to be connected directly to pipelines have access to natural gas because of LNG. In its compact liquid form, natural gas can be shipped in special tankers to terminals around the world. At these terminals, the LNG is returned to its gaseous state and transported by pipeline to distribution companies, industrial consumers, and power plants.

Liquefied Petroleum Gas

The Company produces premium quality Liquefied Petroleum Gas (LPG) used in cooking, refrigeration, metal cutting and fabrication. We provide prompt service through our fully automated loading gantry for timely dispatch of LPG in lorries heading to bottling plants. LPG is a clean gas and is several times more efficient than conventional stoves. The Company supports initiatives of the Government towards proliferation of LPG usage.

The Refinery produces two types of liquefied gas (LPG); the first type consists of a mixture of butane and propane gas, and it is sold in small cylinders of (12.5 kg) and large cylinders of (50 kg). The gas is also sold to some sectors in bulk transported in special tankers. This type of gas is used especially for household purposes.

While the second type is produced in special units and it is used in industry as an alternative to the gases that are harmful to the Ozone layer.

The LPG are petroleum hydrocarbons. His name, liquefied petroleum, coming from turning in the gaseous state which is liquid at atmospheric pressure by compression and cooling, requiring 273 liters of LPG vapor to obtain 1 liter of liquid LPG.

To obtain it, the oil is subjected to an operation called distillation, whereby they separate neatly, according to their densities and boiling points, the various components: light gasoline, kerosene, butane, propane, diesel oil, fuel oil and heavy oils.

The gases from the distillation forming the group are LPG butane (40%) and propane (60%), which are distinguished by their chemical composition, pressure, boiling point and calorific value.

The main uses of LPG